Bio-based Building Materials & Products for Construction: Actors & Stakeholders

Make It Green

Bio-based

Series: Make It Green BIO-01

Article 08/25

Bio-based building materials and products for construction sector: actors and stakeholders

The global construction industry is a major contributor to CO₂ emissions and resource consumption. But what if our buildings could actively help us reducing sources consumptions using products from secondary raw materials? That's the promise of bio-based materials, which are derived from renewable biological resources like plants, animals, and microorganisms. These materials can sequester carbon, reduce reliance on fossil fuels, and offer thermal, acoustic, and health benefits for building occupants at least similar to the traditional products.

However, the transition from conventional to bio-based materials isn't just about the products themselves. It's about a fundamental shift in the entire value chain, driven by a diverse group of stakeholders. From farmers growing the raw materials to policymakers setting new standards, a collaborative ecosystem is essential for success. This requires setting clear targets and measuring impacts to ensure a sustainable and scalable transition.

Actos and Stakeholders working along the bio-based value chain: best practices.

Navigating the landscape of bio-based construction requires understanding the key players and their roles. Here are six best practices that highlight how different actors and stakeholders along the supply chain are collaborating to scale up the use of bio-based materials.

Raw material suppliers (feedstock processor)

A new and critical player in the bio-based ecosystem is the agrowaste player or feedstock processor. These are companies and organizations that specialize in collecting and transforming agricultural by-products, like rice husks, corn cobs, or grape pomace, into usable materials for construction. Crucially, their adoption is boosted by regional innovation anchors like local clusters. A prime example is the Agrifood Clust-ER in the Emilia-Romagna region, Italy. This private association of companies, research centers, and training bodies works to increase the competitiveness of the agri-food sector by connecting its members and focusing on the circular economy and valorization of biomass residues. The impact of this actions can be measured by the tonnage of agricultural waste diverted from disposal (e.g. grape pomace, olive pits) and the volume of new bio-based materials created. The cluster’s direct involvement is measured by the number of joint R&D projects it facilitates that successfully lead to the industrial valorization of agrowaste. At this aim, local clusters create a vital "short supply chain" network that links raw material availability (agrowaste) directly to processing innovation. The Agrifood Clust-ER specifically targets strengthening the resilience of the local bio-economy by identifying new circular production routes (like transforming olive pits into innovative composite materials), effectively turning a regional waste problem into a valuable local resource for the construction sector. With Agrifood Clust-ER and under the coordination of CETMA, Levery is starting a new project of agro-waste chain monitoring.

Consortium projects with value chain players: collaboration in action

The EU-funded WoodToWood project is a prime example of a multi-stakeholder collaboration focused on creating a circular economy for wood. This project unites a diverse consortium of 25 partners, including research institutes, universities, and industry partners (Levery is part of this consortium). Their shared goal is to "upcycle" wood waste from construction and demolition, transforming it into new, high-value materials. The primary metric is the reduction of waste sent to landfills or incineration and the project's success is measured by the volume of wood waste valorized and the carbon emissions avoided. By developing new upcycling technologies, the project aims to reduce the demand for virgin wood and combat deforestation. A key target is to create a comprehensive framework for a multi-dimensional cascade valorization of wood, resulting in products with identical properties to those made from primary resources. This initiative is a step toward making wood waste a standardized feedstock for the European bio-based economy.

The BIOS MATER project is another excellent case study in stakeholder collaboration. It brings together a consortium of 22 partners from 10 different EU countries (Levery is part also of this consortium) to develop and validate four new production routes for bio-based construction products such as flooring systems and tiles. The project measures its success through techno-economic and environmental KPIs. This includes metrics like the lifecycle assessment of new materials, demonstrating their low-carbon footprint and the economic feasibility of their production routes. The main goal is to bridge the gap between research and market adoption. The project aims to develop products that are not only technically viable but also commercially competitive. A core target is to build trust among investors and end-users by using a Safe and Sustainable by Design (SSbD) approach and digital transparency, accelerating the market's transition to bio-based solutions.

Networking Ecosystem

InnovaWood is the largest European network dedicated to research, innovation, and education in the entire forest, wood-based, and furniture sector. It serves as an umbrella organization for over 70 members with leading universities, research institutes and technical centers, facilitating knowledge transfer and project consortia. The network’s impact is measured by its success in shaping the strategic research agenda for the sector also coordinating EU-funded projects (members are involved in hundreds of international projects). A key metric is the number of collaborative projects initiated to address industry-wide innovation gaps. InnovaWood's primary benefit is to increase the competitiveness and innovation level of the European wood industry, especially for SMEs. Its target is to integrate industry needs with research capabilities to drive the use of wood and other bio-based materials in line with EU Green Deal and New European Bauhaus principles.

Another network working to promote biobased products, is the Built by Nature (BbN) network is dedicated to increasing market demand for mass timber and other bio-based materials. As a networking ecosystem, it connects key actors from across the value chain, including developers, architects, investors, and policymakers. The network's impact is measured by the scale of market transformation and the reduction in embodied carbon in buildings. A key metric is the number of pioneering projects it helps to fund and publicize, which demonstrate the feasibility and benefits of bio-based materials. By fostering a community of frontrunners and breaking down barriers through advocacy and knowledge sharing, BbN aims to change perceptions and drive collective action. Their target is to accelerate the shift to a built environment that works in unison with nature, championing forest regeneration and the use of responsibly sourced timber.

Public Policy Maker

Governments are crucial stakeholders in creating a supportive market. The French government provides a strong example with its RE2020 environmental regulation, which mandates the use of bio-based materials in new buildings. This policy promotes wood construction not only for its environmental benefits but also as a way to valorize local resources. The policy's success is measured by a gradual tightening of carbon emission thresholds for new buildings. The regulation sets specific CO₂/m²/year caps that decrease over time (2025, 2028, 2031). RE2020 drives a market shift by incentivizing the use of low-carbon materials and factoring in the carbon-storing benefits of bio-based products like wood. The target is to reduce emissions by at least 30% by 2030 compared to 2013 levels for construction.

Manufacturers

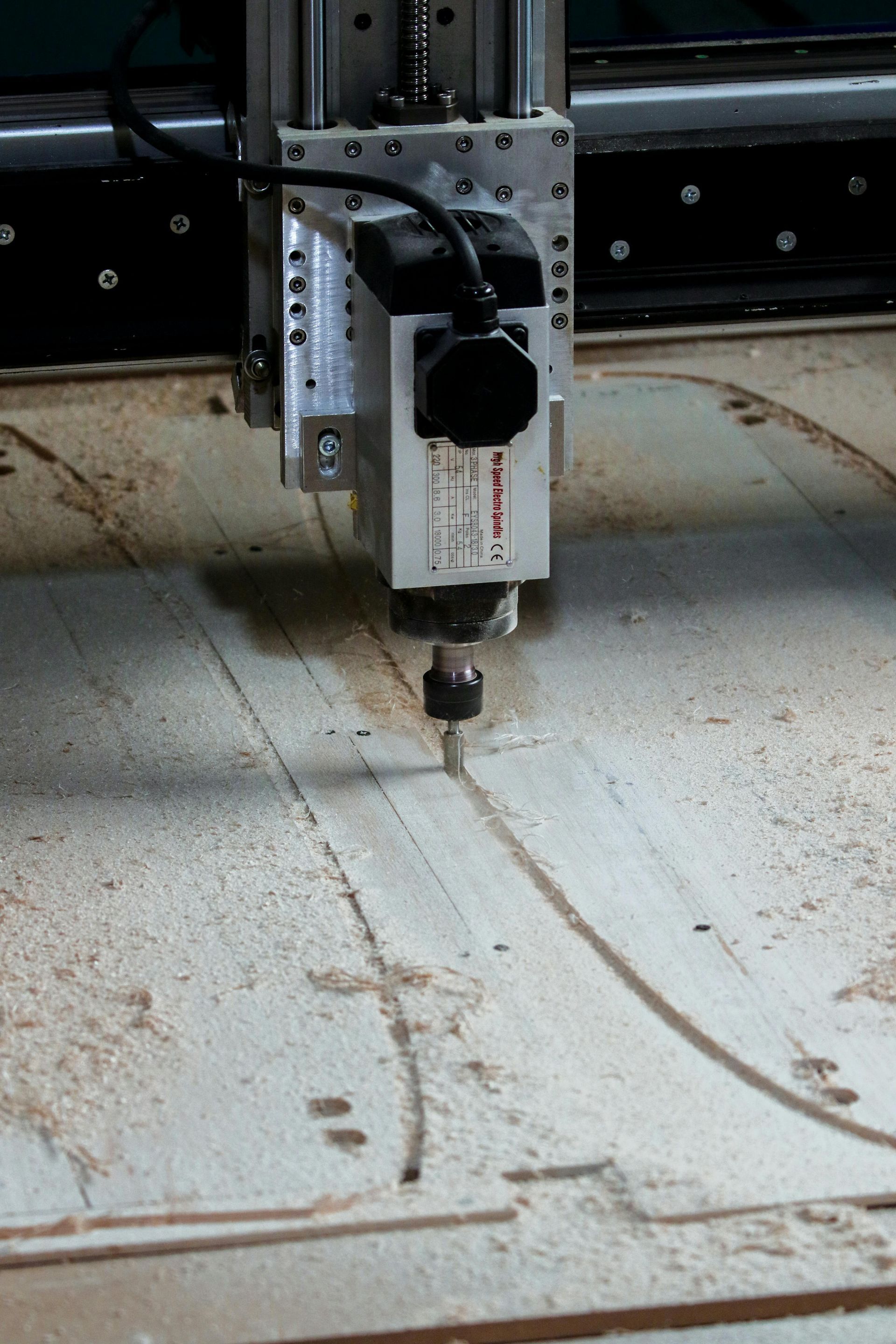

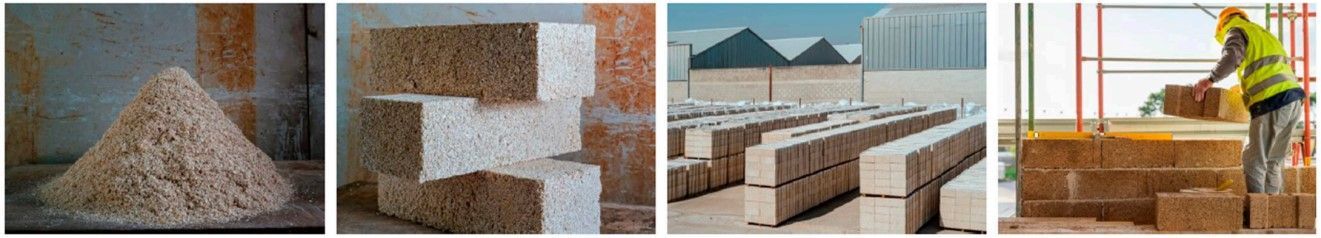

The Italian company Pedone Working is a construction company that operates under the brand Biomat to develop and manufacture new bio-based products. Their focus is on harnessing the potential of hemp, which is potentially cultivated locally in a 0 km supply chain, to create a range of innovative building materials. The primary metric for these hemp-based materials is their ability to be "carbon negative", meaning they absorb more CO₂ during their lifecycle than is emitted in their production. Pedone Working's goal is to revolutionize the way we build by offering products with superior thermal and acoustic insulation. Their products like the Mattone di Canapa (hemp brick) are designed to improve indoor air quality, regulate humidity, and provide high resistance to fire. The target is to provide a complete "carbon-negative" building solution, from bricks to insulation, for high-efficiency and healthy constructions.

Networking Ecosystem

InnovaWood is the largest European network dedicated to research, innovation, and education in the entire forest, wood-based, and furniture sector. It serves as an umbrella organization for over 70 members with leading universities, research institutes and technical centers, facilitating knowledge transfer and project consortia. The network’s impact is measured by its success in shaping the strategic research agenda for the sector also coordinating EU-funded projects (members are involved in hundreds of international projects). A key metric is the number of collaborative projects initiated to address industry-wide innovation gaps. InnovaWood's primary benefit is to increase the competitiveness and innovation level of the European wood industry, especially for SMEs. Its target is to integrate industry needs with research capabilities to drive the use of wood and other bio-based materials in line with EU Green Deal and New European Bauhaus principles.

Another network working to promote biobased products, is the Built by Nature (BbN) network is dedicated to increasing market demand for mass timber and other bio-based materials. As a networking ecosystem, it connects key actors from across the value chain, including developers, architects, investors, and policymakers. The network's impact is measured by the scale of market transformation and the reduction in embodied carbon in buildings. A key metric is the number of pioneering projects it helps to fund and publicize, which demonstrate the feasibility and benefits of bio-based materials. By fostering a community of frontrunners and breaking down barriers through advocacy and knowledge sharing, BbN aims to change perceptions and drive collective action. Their target is to accelerate the shift to a built environment that works in unison with nature, championing forest regeneration and the use of responsibly sourced timber.

Public Policy Maker

Governments are crucial stakeholders in creating a supportive market. The French government provides a strong example with its RE2020 environmental regulation, which mandates the use of bio-based materials in new buildings. This policy promotes wood construction not only for its environmental benefits but also as a way to valorize local resources. The policy's success is measured by a gradual tightening of carbon emission thresholds for new buildings. The regulation sets specific CO₂/m²/year caps that decrease over time (2025, 2028, 2031). RE2020 drives a market shift by incentivizing the use of low-carbon materials and factoring in the carbon-storing benefits of bio-based products like wood. The target is to reduce emissions by at least 30% by 2030 compared to 2013 levels for construction.

Manufacturers

The Italian company Pedone Working is a construction company that operates under the brand Biomat to develop and manufacture new bio-based products. Their focus is on harnessing the potential of hemp, which is potentially cultivated locally in a 0 km supply chain, to create a range of innovative building materials. The primary metric for these hemp-based materials is their ability to be "carbon negative", meaning they absorb more CO₂ during their lifecycle than is emitted in their production. Pedone Working's goal is to revolutionize the way we build by offering products with superior thermal and acoustic insulation. Their products like the Mattone di Canapa (hemp brick) are designed to improve indoor air quality, regulate humidity, and provide high resistance to fire. The target is to provide a complete "carbon-negative" building solution, from bricks to insulation, for high-efficiency and healthy constructions.

CONCLUSIONS

The shift to bio-based materials in construction isn't just a trend, it's a systemic change requiring the coordinated effort of a wide array of stakeholders. From pioneering companies consortia (also thanks to EU-funded projects) that build a new circular value chain, to the emergence of agrowaste processors who turn agricultural by-products into building blocks, we're seeing a collaborative push toward a greener future. Public policy, as seen in France, and innovative manufacturers like Pedone Working, further demonstrate the power of a multi-faceted approach. At Levery, we're proud to be part of this movement, helping to connect these different worlds and accelerate the transition to a truly sustainable built environment.

REFERENCES

- Clust-er Agrifood Website. https://agrifood.clust-er.it/

- WoodToWood Project Website. www.wood2wood-project.eu

- BIOS MATER Project Website. https://biosmater.eu/

- Wood2Wood Projeect Website. https://www.wood2wood-project.eu/

- Built by Nature. https://builtbn.org/

- Innovawood Website. https://innovawood.com/

- Pedone Working. https://pedoneworking.it/m

- Biomat Canapa. https://biomatcanapa.it/

- Ministère de l'Agriculture et de la Souveraineté alimentaire, "Building with Wood: Environmental and Economic Potential - Analysis n°211". https://agriculture.gouv.fr/building-wood-environmental-and-economic-potential-analysis-ndeg211

This research is funded by the European Union (Project: W2W, GA 101138789101096139). However, the points of view and opinions expressed are those of the Authors only and do not necessarily reflect hose of the European Union. Neither the European Union nor the granting authority can be held responsible for them

CALL FOR ACTION

Start your Bio-based products journey today with Levery and transform your construction projects or your building products into energy-generating, future-ready buildings. Let’s work together to create buildings that benefit people, enviroment and economic.

Contact us now to discuss how we can help you integrate solar power into your next project and drive the shift toward a greener future.