Robotic & Automation for Construction: Actors & Stakeholders

Make It Digital

Robot&Automation

Series: Make It Digital Rob-01

Article 11/25

Robotic & Automation for Construction: Actors & Stakeholders

The global construction industry is actively embracing its next major evolution, driven by the critical need for increased safety, productivity and predictability. This transformation is embodied by the rise of Robotics and Automation (R&A). Moving beyond single-task tools, R&A is integrating into the entire construction lifecycle, from design to execution and monitoring.

The success of this shift relies on a sophisticated Networking Ecosystem where technology creators, research entities, large industry players and end-users collaborate to prove the value and scalability of automated solutions. The stakeholders driving this evolution are defined by their unique contribution to bridging the gap between digital planning and physical building.

Actors and Stakeholders working along the automation and robotic value chain: best practices

The most effective progress in construction robotics is being made by distinct actors specializing in different parts of the digital value chain.

Equipment machinery manufacturers: the product innovator

This category comprises the companies responsible for productizing specific, high-value robotic applications. A prime example is Hilti Group, a global leader in construction tools and equipment. Hilti’s role extends beyond mere sales; they strategically partner with specialists to industrialize robotic solutions. For instance, the Hilti Jaibot , a semi-autonomous drilling robot, is a result of their long-standing strategic collaboration, which has included work with the Norwegian startup nLink since 2021. This partnership leverages Hilti’s market access and safety standards with nLink’s robotics expertise, successfully automating the strenuous and dangerous task of overhead drilling for MEP installations directly from a digital plan. This synergy demonstrates how incumbents can integrate with agile startups to rapidly scale innovation and immediately improve on-site safety and efficiency.

Fig. 1 - AMALTEA project: robotics technologies

Equipment machinery manufacturers: the product innovator

This category comprises the companies responsible for productizing specific, high-value robotic applications. A prime example is Hilti Group, a global leader in construction tools and equipment. Hilti’s role extends beyond mere sales; they strategically partner with specialists to industrialize robotic solutions. For instance, the Hilti Jaibot , a semi-autonomous drilling robot, is a result of their long-standing strategic collaboration, which has included work with the Norwegian startup nLink since 2021. This partnership leverages Hilti’s market access and safety standards with nLink’s robotics expertise, successfully automating the strenuous and dangerous task of overhead drilling for MEP installations directly from a digital plan. This synergy demonstrates how incumbents can integrate with agile startups to rapidly scale innovation and immediately improve on-site safety and efficiency.

Construction robotics companies: the disruptive builder

These innovators focus on the complete automation of core, labor-intensive construction trades. FBR Limited, through its development of the Hadrian X robot, is fundamentally challenging traditional masonry. The Hadrian X is designed to be the world's first fully autonomous bricklaying system, capable of constructing the walls of a house in less time than required by manual methods. It operates on a truck-mounted platform, using a telescopic boom to lay proprietary blocks with high precision based on 3D CAD data. By using a fast-curing adhesive instead of mortar, FBR aims to achieve unprecedented lay rates and minimal material waste, positioning itself as a disruptive force in the structural building phase.

Monitoring and data automation providers: the digital eye

The ability to accurately and frequently monitor site progress is crucial for automation to deliver on its promise of predictability. Companies like Boston Dynamics, with their versatile Spot quadruped robot, and FARO Technologies, following its acquisition of HoloBuilder, are leading this effort. Spot, the agile mobile robot, is utilized to perform autonomous, repeatable site walks, capturing vast amounts of data. This data is then often processed by systems like the platform from FARO/HoloBuilder, which creates 360-degree virtual records of the jobsite, linking captured reality directly to the BIM model. This collaboration turns data into actionable insights, providing project managers with a real-time "digital eye" to track progress, ensure quality control, and document every phase of construction.

Fig. 2-3 - Hadiramn project (credit FBR)

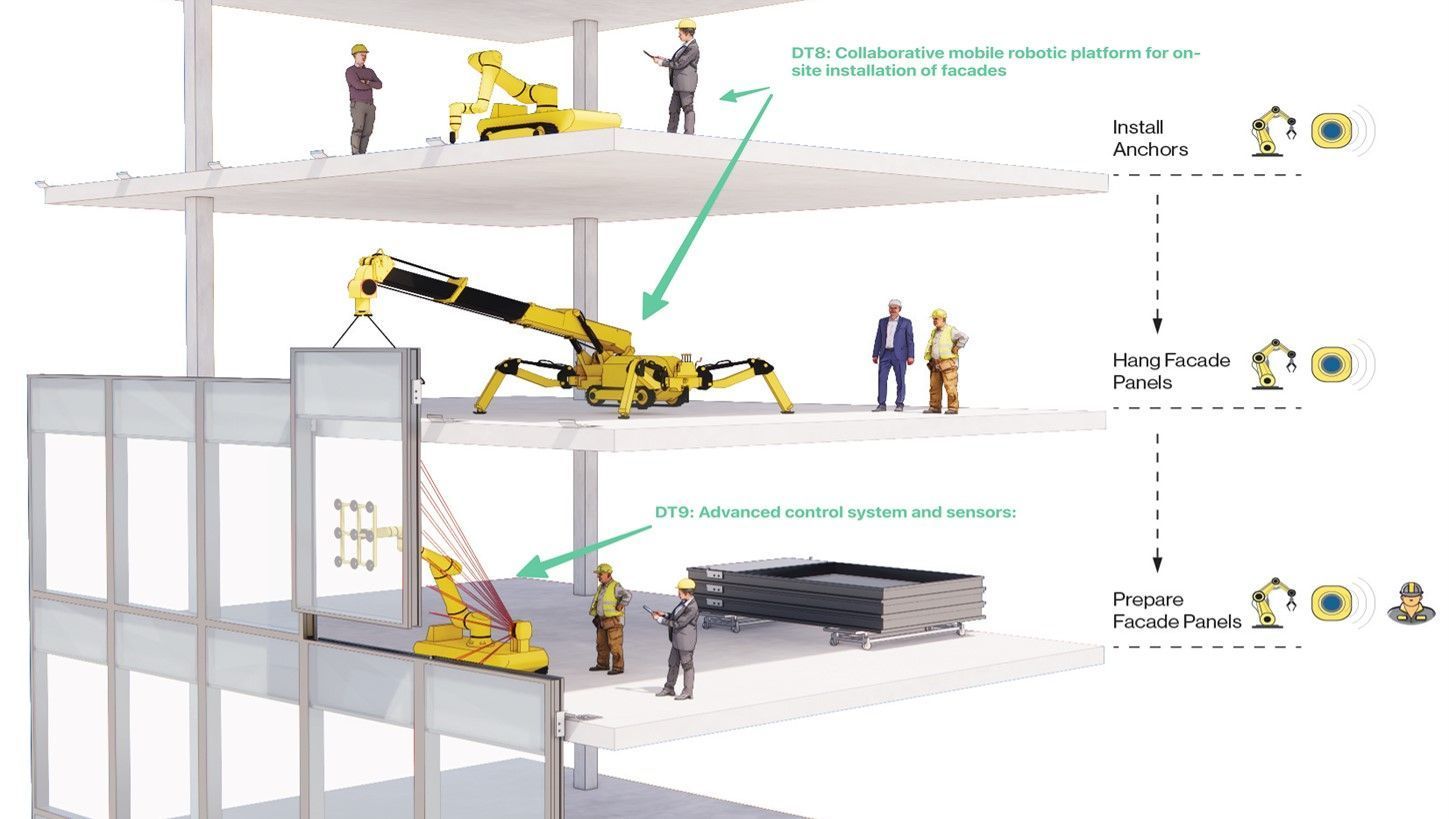

Consortium projects: the integration catalyst

Complex technological leaps often require non-commercial collaborative efforts involving research, industry and academia. The AMALTEA consortium exemplifies this, focusing on a deep integration challenge: the full lifecycle automation of modular facades. This Horizon Europe project brings together Research and Technology Organizations (RTOs), universities, architects and robot manufacturers to combine Artificial Intelligence (AI), robotics and Digital Twins. Their collective goal is to validate a single, streamlined digital-to-physical process for buildin envelope system from design through manufacturing up to construction stage, proving that automation can be both sophisticated and scalable while meeting high standards for sustainability and efficiency.

General contractors and system integrators: the end-user driver

Ultimately, the commercial success of construction robotics rests with the General Contractors (GCs) who implement and scale these solutions across projects. Skanska, one of the world's leading GCs, is an active pioneer in the use of robotics. Skanska’s activities, such as testing the Boston Dynamics Spot robot for novel applications like post-construction site cleanup, demonstrate a commitment to pushing the envelope beyond standard use cases. By integrating these machines and defining the protocols for their operation, GCs like Skanska drive the market for interoperability and set new benchmarks for efficiency and safety that the rest of the industry must follow. Their investment is the final proof point that automation is financially and operationally viable.

Fig. 4-5 - Hilti robot technologies

Conclusions

The transition to a digital construction site is fundamentally an ecosystem challenge, not just a technical one. The innovation driven by product developers like Hilti, the disruption brought by builders like FBR, the essential monitoring provided by Spot and HoloBuilder, the research catalyzed by consortia like AMALTEA and the real-world adoption championed by GCs like Skanska, all these pieces are essential. The collaborative efforts across this value chain are what is truly accelerating the pace of change, replacing dangerous, repetitive manual labor with sophisticated, data-driven automation, and ushering in an era of predictable and high-quality building.

References

Hilti USA. Jaibot Semi-Autonomous Drilling Robot

nLink Robotics. Our Story

Skanska USA. Meet Spot: A robot that’s being tested to clean construction jobsites

AMALTEA homepage - Amaltea Project

FBR Limited. Hadrian X Product Information. Hadrian® | Automated Construction Robot from FBR

Holobuilder (now a FARO Technologies Company). HoloBuilder™ Software | Software | FARO

CALL FOR ACTION

Start your Robot and Automation products journey today with Levery and transform your construction projects or your building products into energy-generating, future-ready buildings. Let’s work together to create buildings that benefit people, enviroment and economic.

Contact us now to discuss how we can help you integrate solar power into your next project and drive the shift toward a greener future.