Bio-based building materials & products for construction: innovative technologies

Make It Green

Bio-based

Series: Make It Green BIO-02

Article 01/26

Bio-based building materials & products for construction: building components and elements

The transition toward a sustainable built environment relies on the physical integration of low-impact materials into building structures. Following our analysis of the stakeholders driving this sector, we now focus on the products currently under development that are redefining the performance of both the building envelope and internal systems. These materials are moving beyond traditional timber to include high-performance composites derived from agricultural waste, fungi, and bio-polymers, aiming to replace carbon-intensive plastics, mineral wool, and concrete with alternatives that act as active carbon sinks.

The evolution of the bio-based building envelope

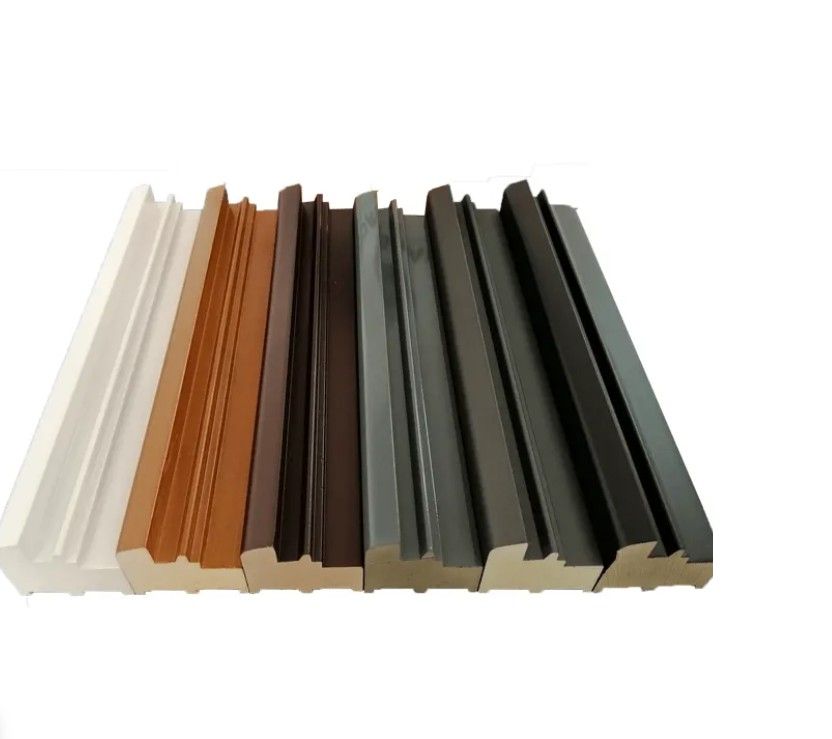

The building envelope serves as the primary interface for energy efficiency, and current innovation is focused on optimizing thermal regulation through biological feedstock. In the sector of openings and frames, Indresmat has developed a thermal-break window frame solution using a proprietary bio-based polyurethane. By using natural oil based raw materials up to 65-75% biosourced materials, they produce frames that offer windows with thermal transmittance values (0,88 W/m2K) exceeding current regulatory requirements while reducing C-Footprint that replace 100% fossil based polyurethane applications for insulation.

Thermal insulation is also being transformed by the use of mycelium and wood waste. Mykor produces highly insulating panels by growing fungal root structures on industrial wood residues. This process creates a carbon-negative product that sequesters more carbon during its growth phase than is emitted during its processing. These panels achieve thermal conductivity levels comparable to mineral wool but offer superior acoustic performance and fire resistance without the use of toxic chemicals.

Complementing these solutions are advanced bio-foams and bioceramics, such as those developed by 4D-Mater. Their "Grow-Foams" leverage porous biological structures to provide a high strength-to-weight ratio, offering a lightweight alternative for infill panels and partitions. Similarly, for structural and infill masonry, the Mattone di Canapa by Biomat (Pedone Working) represents a mature solution. This hemp brick, composed of hemp shives and natural lime binders. It provides high thermal inertia and regulates indoor humidity, ensuring superior hygrometric comfort for occupants a circular business model using hemp cultivation waste.

Fig. 1 |Mykor insulation panel (credit: Mykor)

Fig. 2 | Indresmat PUR window frame (credit: Indresmat)

Bio-based solutions to interiors, load bearing structure and furniture

Innovation in the bio-based sector is not limited to the external shell; it is increasingly impacting internal building systems, structural components, and finishes. Interior acoustic comfort is being redefined by companies like Mogu, which utilizes mycelium technology to create functional interior modules. Their acoustic panels are grown from fungal strains on upcycled textile and agricultural residues. These products provide high-performance sound absorption while remaining entirely biodegradable and VOC-free, contributing to healthier indoor air quality in commercial and residential spaces.

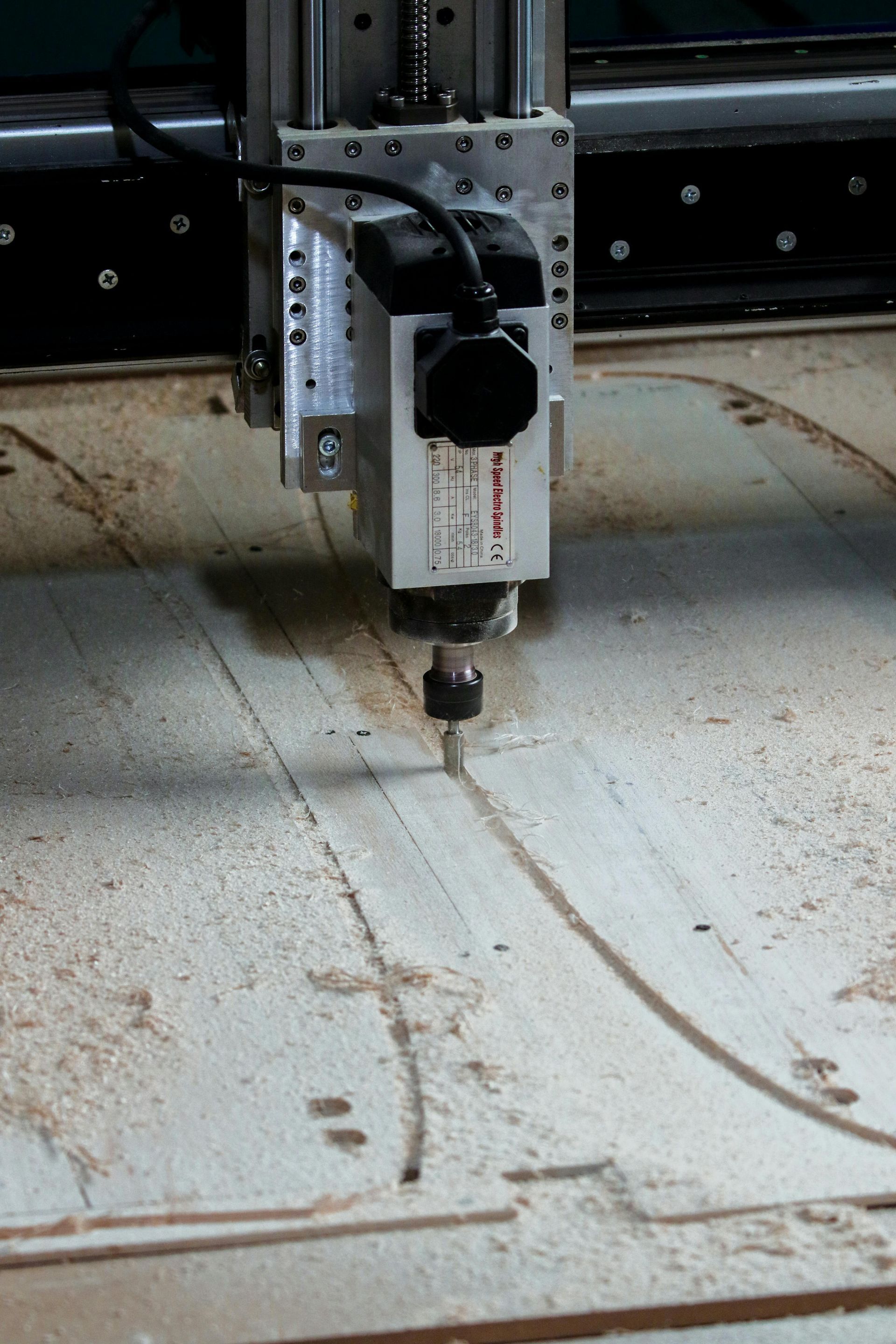

In the realm of structural systems, StrongByForm is pioneering the use of bio-composites through their "Woodflow" technology. This process allows for the creation of high-performance structural components by optimizing the direction of wood fibers in a way that mimics natural growth patterns. By using digital fabrication to combine wood with bio-resins, they produce lightweight structural elements that can replace steel or concrete in specific applications, maximizing the efficiency of timber resources and reducing the overall weight of the building structure.

Even high-moisture environments such as bathrooms are seeing the introduction of bio-based alternatives. Woodio has developed a water-resistant wood composite used for sanitaryware, including sinks and toilets. Traditionally, ceramic production is highly energy-intensive due to kiln firing; Woodio’s material uses wood chips and a bio-based resin binder to create durable, carbon-storing products with a significantly lower carbon footprint. This demonstrates that the biological transition can reach every corner of the construction value chain, providing a holistic approach to building decarbonization.

Fig. 3 Mogu indoor panel (credit: Mogu)

Fig. 4 | StrongByForm "Woodflow" (credit: Strongbyform)

Conclusion

The physical products available today prove that bio-based materials are no longer limited to niche applications. From the bio-polyurethane frames of Indresmat and the carbon-negative masonry of Biomat to the structural bio-composites of StrongByForm, these components provide a proactive solution to the construction industry’s environmental challenges. By integrating these grown and bio-manufactured elements across all building systems, the sector can achieve the dual benefit of reducing embodied carbon during construction and improving efficiency during operation. At Levery, we view the adoption of these standardized, high-performance bio-components as a fundamental step toward a truly sustainable and human-centric built environment.

References

Indresmat. Indresmat Bio-based Windows

Mykor. Mycelium Insulation Technology

4D-Mater. Grow-Foams and Bioceramics

Biomat Canapa. Mattone di Canapa - Canapafor Line

Mogu. Mycelium for Interior Design

StrongByForm. Structural Woodflow Technology

Woodio. Bio-based Wood Composite Sanitaryware

Levery S.r.l. Società Benefit. Bio-based building materials and products for construction sector: actors and stakeholders

This research is funded by the European Union (Project: BIOS MATER, GA 101214808). However, the points of view and opinions expressed are those of the Authors only and do not necessarily reflect hose of the European Union. Neither the European Union nor the granting authority can be held responsible for them.

CALL FOR ACTION

Start your Bio-based products journey today with Levery and transform your construction projects or your building products into energy-generating, future-ready buildings. Let’s work together to create buildings that benefit people, enviroment and economic.

Contact us now to discuss how we can help you integrate solar power into your next project and drive the shift toward a greener future.