Robotic & Automation for Construction: Robotic Products for Digital Workflows

Make It Digital

Robot&Automation

Series: Make It Digital Rob-02

Article 02/26

Robotic & Automation for Construction: Robotic Products for Digital Workflows

The systemic change toward a digitally integrated construction site could be enhanced on the physical deployment of robotic units capable of bridging the gap between digital representation of built environment via CAD and BIM, and jobsite execution. Following our analysis of the stakeholders driving this evolution, we now focus on some of the robotic products which are currently optimizing tasks automation and addressing human augmentation tasks deployment. These technologies address core industry challenges: labor shortages, safety risks in repetitive tasks, and the persistent productivity gap.

By classifying these solutions based on their field of application, ranging from general building operations to specialized infrastructure works, we can observe how automation is replacing manual, error-prone processes with high-precision digital execution. The perspective is to transition from traditional manual labor to a proactive, data-driven construction environment.

Automated construction operations and site execution

Building on-site operations: layout and structural masonry

The initial phase of any on-site operation requires the precise translation of digital designs into physical coordinates. The HP SitePrint layout robot serves this specific function, autonomously printing complex floor plans directly onto the jobsite slab. By integrating directly with cloud-based BIM data, the system eliminates the traditional, manual marking process. Its impact is measured by the reduction in layout time and the high-fidelity alignment between the "as-designed" and "as-built" setting out, preventing downstream errors.

Moving from layout to structural assembly, the FBR Hadrian X represents a significant shift in autonomous masonry. This truck-mounted system utilizes a telescopic boom to lay structural blocks according to a 3D CAD model. By using a specialized adhesive instead of traditional mortar, the Hadrian X achieves high lay rates and structural precision with minimal material waste. This application is highly effective for residential and commercial building shells where speed and consistency are primary drivers for schedule optimization.

Fig.1 - HP Siteprint

Infrastructure operations: specialized heavy automation

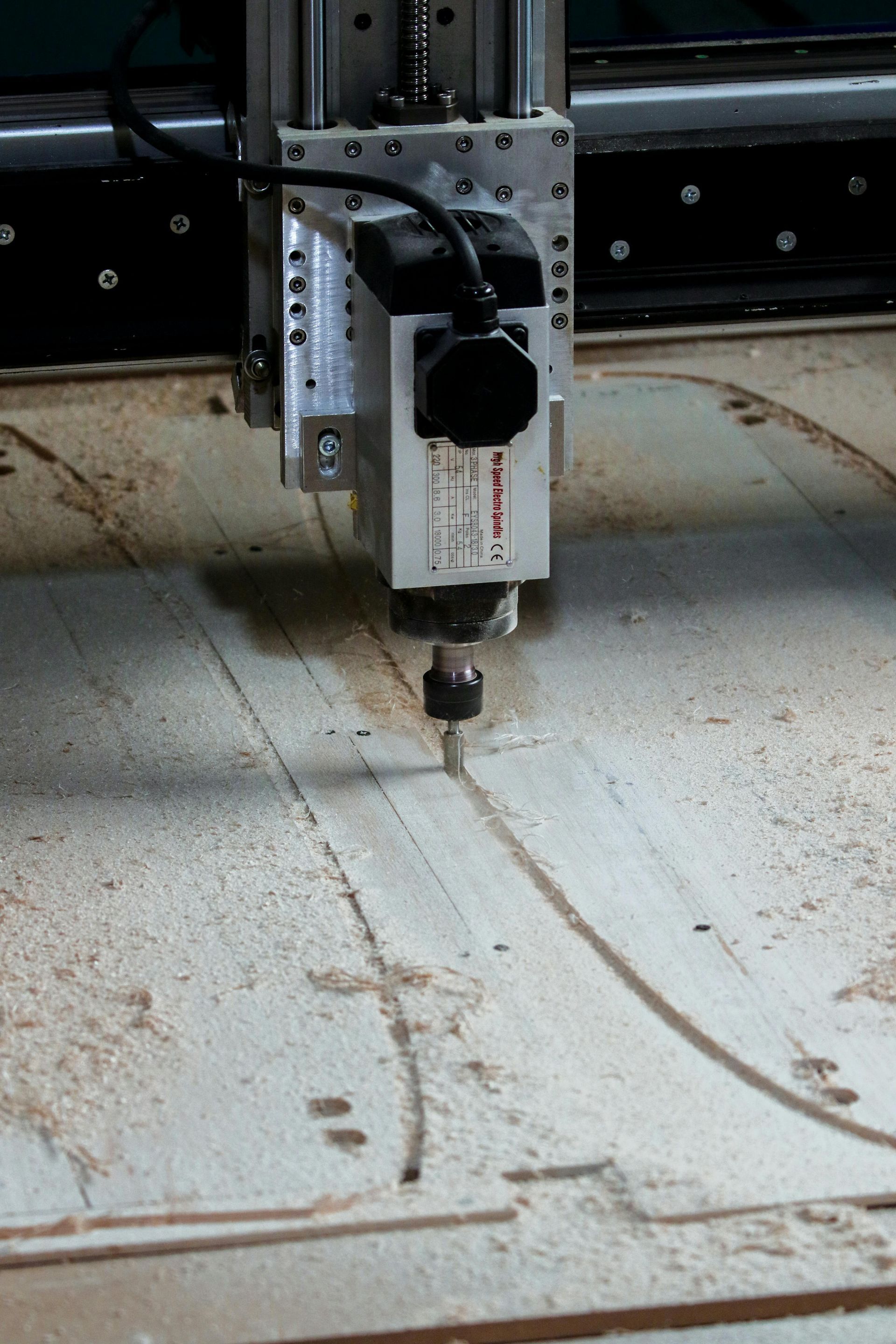

Large-scale infrastructure projects, such as bridges and highways, require automation capable of handling high-volume, repetitive structural tasks. The Advanced Construction Robotics TyBot is a specialized autonomous solution for rebar tying on bridge decks. The TyBot navigates the rebar mat autonomously, identifying and tying thousands of intersections without manual intervention. This allows human crews to focus on complex placement while the robot manages the critical path of reinforcement. The primary metric for TyBot is the increase in ties per hour and the reduction in musculoskeletal risks for workers.

For large-scale earthworks, the Built Robotics Exosystem provides a scalable solution for infrastructure and energy projects. This AI-driven aftermarket kit transforms standard heavy machinery, such as excavators, into fully autonomous robots capable of performing complex trenching and digging tasks. Utilizing GPS, LiDAR, and computer vision, the system allows equipment to operate without an on-board operator, ensuring consistent excavation depth and precision. The adoption of this technology facilitates 24/7 operations, effectively removing workers from hazardous trenching environments and increasing site productivity by up to 30%.

Fig. 2 - Tybot robot

Finishing and interior installation systems

Once the structure is established, interior finishing and MEP (Mechanical, Electrical, and Plumbing) installations require precise, semi-autonomous movements. The Hilti Jaibot is a mobile drilling robot designed for overhead MEP installations. This product is the result of a strategic collaboration between Hilti and the Norwegian startup nLink, aimed at automating strenuous drilling tasks. By following BIM-defined coordinates, the Jaibot executes precise anchor holes, ensuring that all ceiling-mounted systems are installed exactly where the digital plan dictates.

Complementing this is the Canvas (a JLG company) drywall finishing robot. This system automates the spraying and sanding of joint compound, achieving consistent finishes. The use of Canvas reduces the time required for finishing while protecting workers from the respiratory and physical strain of manual sanding. Its integration into the workflow ensures that interior quality is maintained at a high industrial standard regardless of labor availability.

Cross-cutting site intelligence and monitoring

A fundamental component across both building and infrastructure fields is the ability to monitor progress autonomously. The Boston Dynamics Spot robot, often utilized by contractors like Skanska for site monitoring and novel applications such as debris management, serves as a mobile sensing platform. When integrated with FARO/HoloBuilder technology, Spot performs autonomous site walks to capture 360-degree imagery and laser scans. This data is fed into digital twin platforms, providing stakeholders with real-time visibility into project status and replacing sporadic, manual site inspections with continuous, objective documentation.

Fig. 3 - Canvas robot

Conclusions

The robotic products currently available for the construction sector demonstrate a clear move toward specialized, task-oriented automation. From the HP SitePrint's layout accuracy to the heavy-duty infrastructure capabilities of TyBot and the interior precision of the Hilti Jaibot and Canvas, these machines are redefining the jobsite. By delegating repetitive, dangerous, and high-precision tasks to robotic units, the construction industry achieves higher productivity and safer working conditions. At Levery, we recognize that the future of construction is centered on the seamless integration of digital intelligence and robotic execution.

References

HP SitePrint. Layout Robot Technology

JLG Canvas. Drywall Finishing Robot

Advanced Construction Robotics. TyBot Rebar Tying Robot

Built Robotics. Exosystem for Autonomous Earthmoving

FBR Limited. Hadrian X Autonomous Masonry

Hilti Group. Jaibot Semi-Autonomous Drilling

nLink Robotics. Our Story and Hilti Collaboration

Skanska USA. Spot the Robot on the Jobsite

Boston Dynamics. Spot for Construction Monitoring

Levery S.r.l. Società Benefit. Robotic & Automation for Construction: Actors and Stakeholders

CALL FOR ACTION

Start your automation journey today with Levery and transform your construction projects or your building products into energy-generating, future-ready buildings. Let’s work together to create buildings that benefit people, enviroment and economic.

Contact us now to discuss how we can help you integrate robotic solutions into your next project and drive the shift toward a greener future.